Bosch Rexroth - Netherlands

|

As a global partner, Bosch Rexroth supports mechanical and plant engineering efforts around the world with its cutting-edge technology and unique industry knowledge. More than 31,100 associates across the globe are developing tailored, safe and resource-friendly solutions.

Our innovations deliver multi-dimensional enhancements for machine manufacturers and end users. For example, they help to reduce harmful carbon dioxide emissions while simultaneously raising productivity.

Above all, we make it easy to use cross-technology solutions by means of predefined functions and integrated engineering tools.

| Transfer system (RAS/FAS) |

|

Transfer system

Bosch Rexroth is an experienced partner when it comes to different types of transfer systems. All systems are based on either replenishing ships at sea with solid goods or refueling ships with liquids.

Seaworthy transfer systems

The process of replenishment and refueling ships at sea can take place in critical situations, from being underway in rough weather conditions to experiencing freezing temperatures at the arctic seas. In order to ensure a safe and reliable exchange of solid goods and fluids in various conditions at sea, Rexroth transfer systems meet the highest industry quality standards with respect to technology, functionality, safety, economy and class conformity. As a partner already in the engineering phase, Rexroth is able to develop transfer systems meeting these highest industry standards plus it can save you maintenance time and costs, not to mention improving availability over the complete life cycle.

Electric & hydraulic transfer systems

Throughout the years Bosch Rexroth delivered both electrical and hydraulics-based transfer systems. Hydraulics are usually more compact, and may have advantages in power consumption. In case hydraulic power is already available in the ship’s design a substantial reduction on the costs can be expected by using hydraulic replenishment solutions. Electrical transfer systems on the other hand are less complex and easier to maintain.

|

| Helicopter handling systems |

|

Helicopter handling systems

Upon landing on the helideck of a ship or a platform, most helicopters attach themselves automatically to a grid in the landing deck. A Helicopter Handling System is subsequently used to move the helicopter in a controlled and safe way into its hangar and from the hangar back to the take-off position. For this type of handling of the helicopter a number of different systems and methods are in existence, ranging from winch-and-rope systems to fully automated transfer systems.

Rail

The helicopter transfer system - Rail was designed as a cost-effective system to handle large and relatively heavy loads, from many different types of helicopter. The system design is based on a double rail system with rails flush integrated into the ship’s deck structure. This set of rails provides guidance for the towing beam that is connected to two rail travelers inside the rails. The rail travelers are connected to wire ropes and are driven by two hydraulically operated winches in the hangar.

Winch

The helicopter handling system -Winch system consists of a 3 or 4 winch concept with wire-ropes running via sheaves to strong points of the helicopter. During handling, the helicopter will be subject to the ship’s motion and the wind force. In order to keep the helicopter restrained and moving correctly without wheel slippage, the wire tension in each winch has to be varied constantly, meanwhile avoiding that non-admissible loads are exerted on the helicopter. Dependent on different parameters a 3 or 4 winch solution may be chosen, as well as a hydraulically controlled system or a computer controlled system. A winch-and-cable system is very cost-effective and can be used for various types of helicopter, and is very suitable for small- or medium-sized helicopters. For most installations, the system will require only minor modifications to the ship. |

|

"PLEASE DO NOT HESITATE TO CONTACT US FOR FURTHER INFORMATION"

Email : t.worayutthakarn_pete_f@yahoo.com Mobile : +66 95 740 7404

Credit : https://www.boschrexroth.com/en/xc/industries/machinery-applications-and-engineering/marine/products-and-solutions/transfer-systems/index

|

| Release |

Pluto Gigas

|

Decoy Launcher

|

Gyro compass (Fiber-optic)

|

|

PLUTO GIGAS is the heavier Idrobotica ROV (Remotely Operated Vehicle) having a primary use as a heavy duty MINE IDENTIFICATION and MINE DISPOSAL, in prohibitive conditions.

|

SYLENA LW (Light Weight) - Anti RF/IR missiles SYLENA MK1 - Anti RF/IR missiles SEAMOSC Launcher (option) - Anti EO/Laser missiles SYLENA MK2 - Anti RF/IR missiles and electro-acoustic torpedoes SYLENA MK2 IN - «below the deck» stealth Integration SEAWAKE Launcher (option) - Anti Wake Homing Torpedoes. |

MARINS M-Series includes three performance grades and is based on the iXBlue FOG latest technology, proven for superior reliability and performance

|

|

Helicopter Visual Landing Aid System

|

Engine and generator

|

High pressure air compressor

|

|

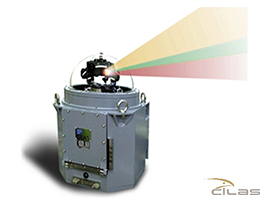

SAFECOPTER, the Helicopter Visual Landing Aid System (HVLAS) by CILAS, ensures helicopter crew’s safety, night and day, on all the seas and oceans of the world.

|

MAN Diesel & Turbo’s synthesis of world-class engineering and state-of-the-art technology. This engine brings highly efficient, reliable, economical and environmentally friendly solutions to the propulsion requirements of our marine customers. |

CompAir, we have the ability to understand our customer’s specific requirements and are committed to ensuring we provide intelligent solutions that meet your ultimate needs for high pressure applications.

|

|

|